Leaders in technology and trust

We specialize in the design and manufacture of highly technical molds. Our career began in 1986. Since then, we have continually evolved and made progress, always reaching our goals and incorporating new challenges every day.

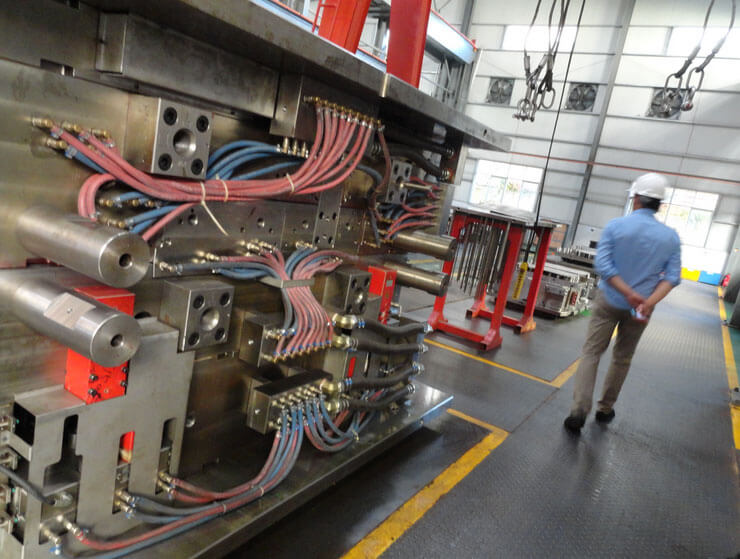

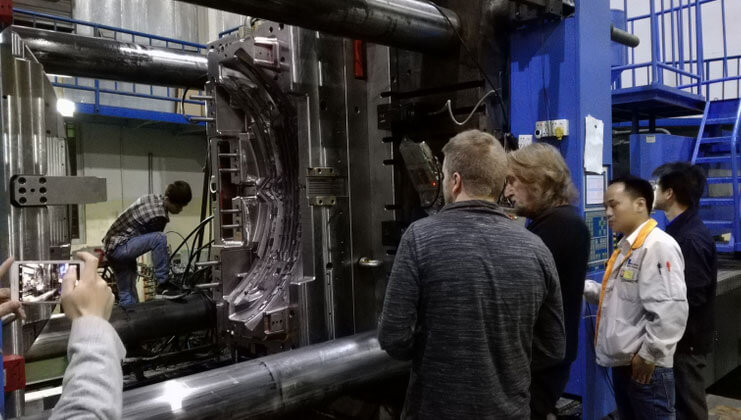

Investing in a comprehensive solution of our tools delivers the best return on investment in the industry with the lowest risk. As partners, we are responsible for the entire line of work, including machine, mold, hot runner, temperature controller and ancillary equipment. We can help you plan your manufacturing production and oversee the setup, delivery and commissioning. In addition, we also offer the most complete after sales support programs in the industry.

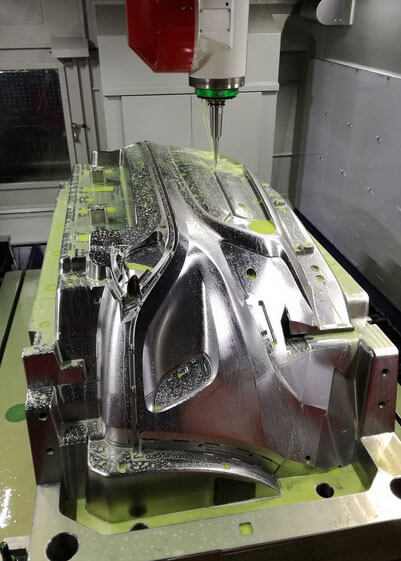

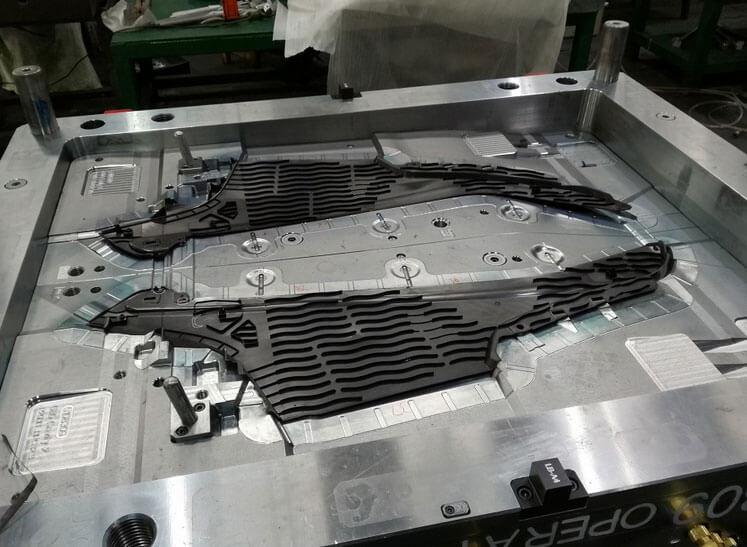

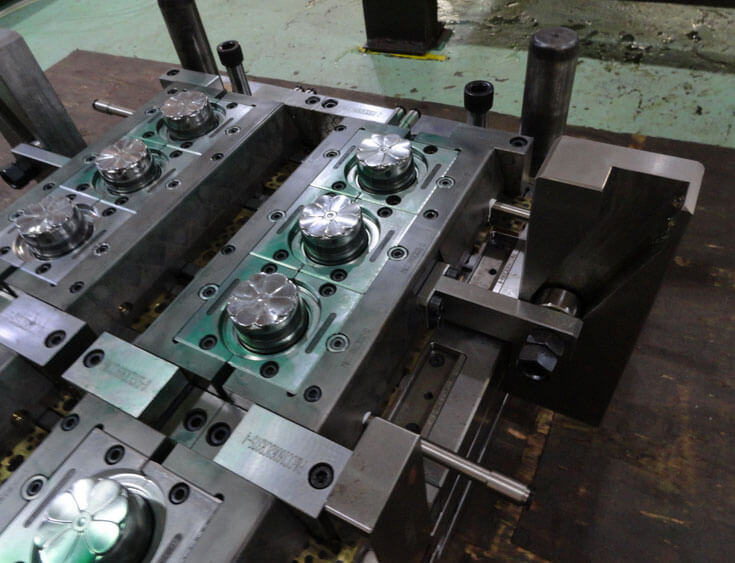

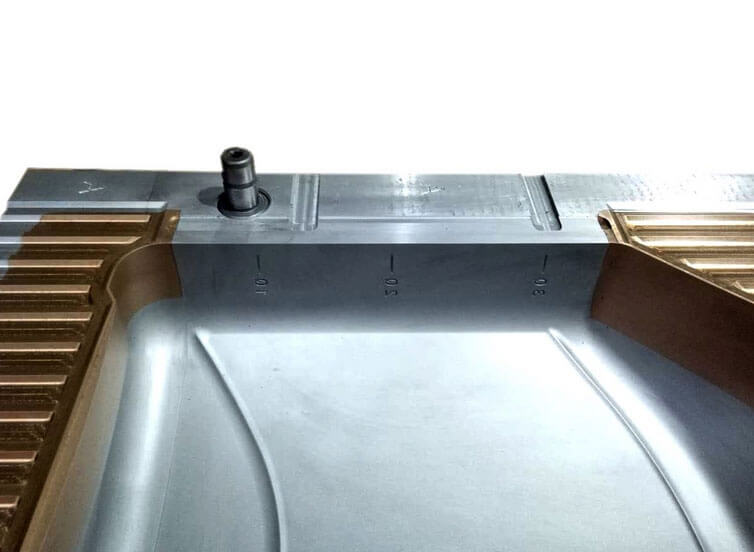

done_all INJECTION MOLDS

Extensive local market experience in the plastics industry, providing the most varied molds for various product areas, 10 years developing molds made in Asia with the relevant qualities for each project, and representing the most prestigious Asian Plastic Injection Machines. The dedication and constancy of our company in recent years, always added by the guarantee of functionality of our represented products, gives our customers complete confidence.

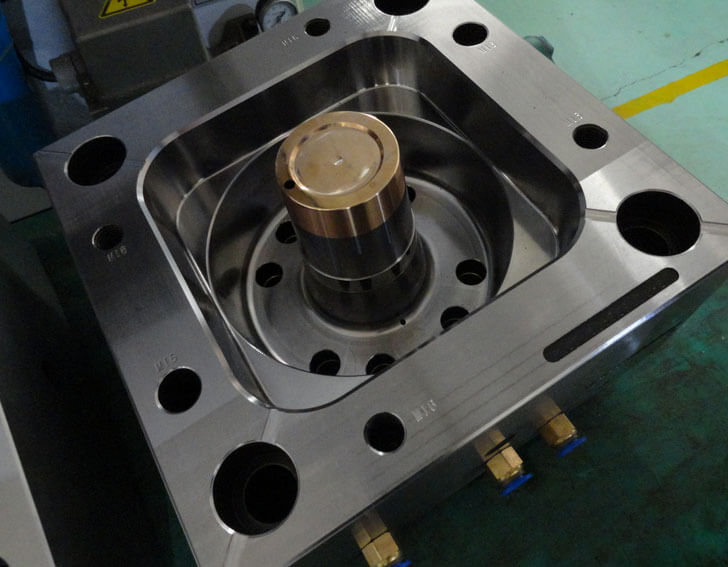

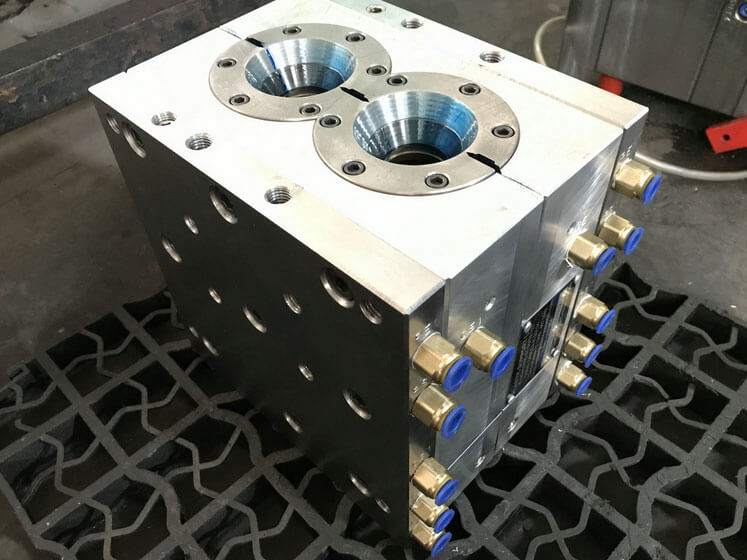

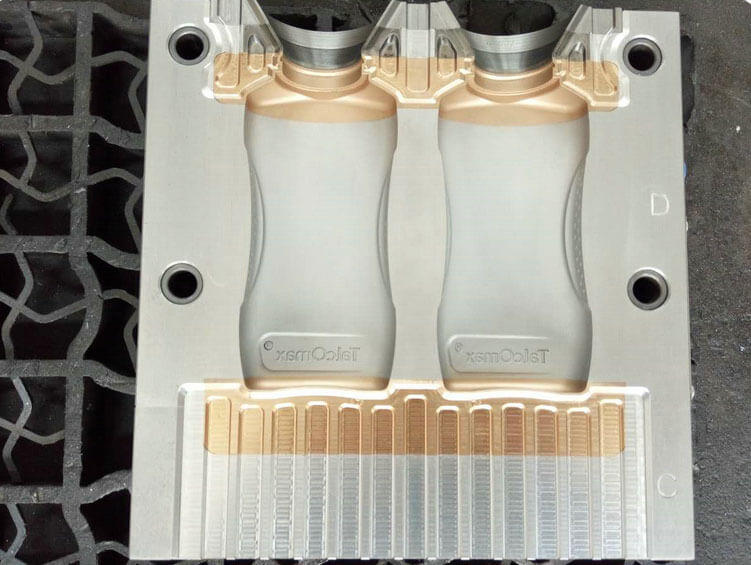

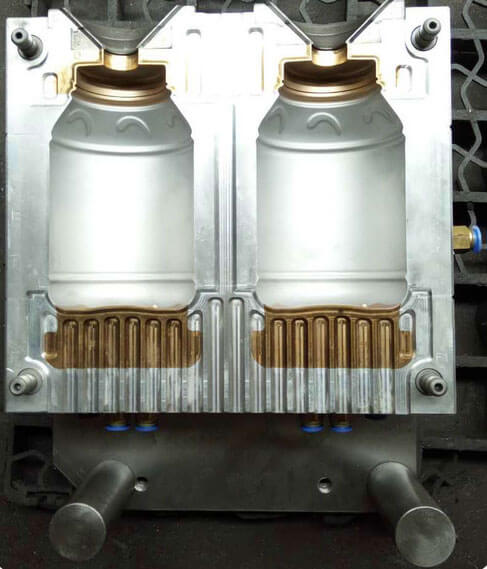

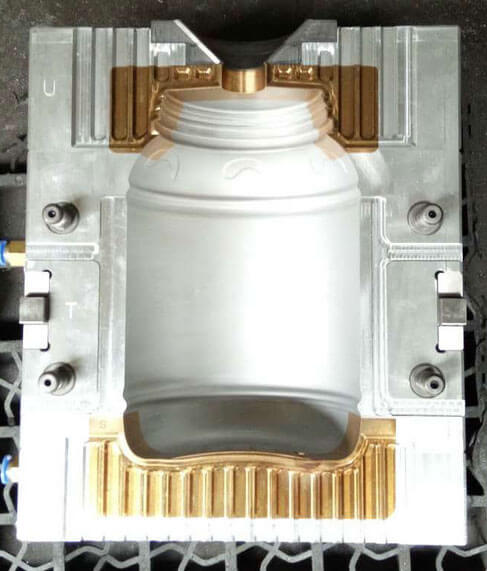

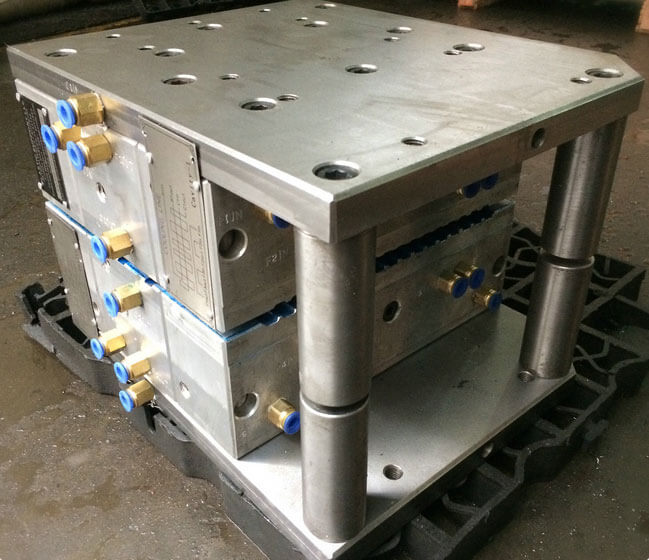

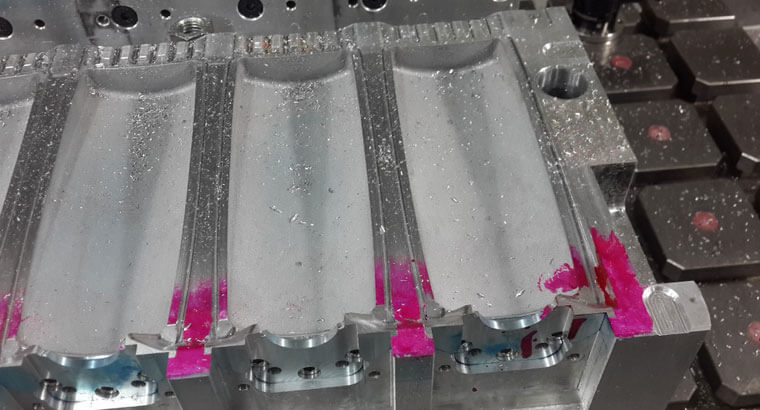

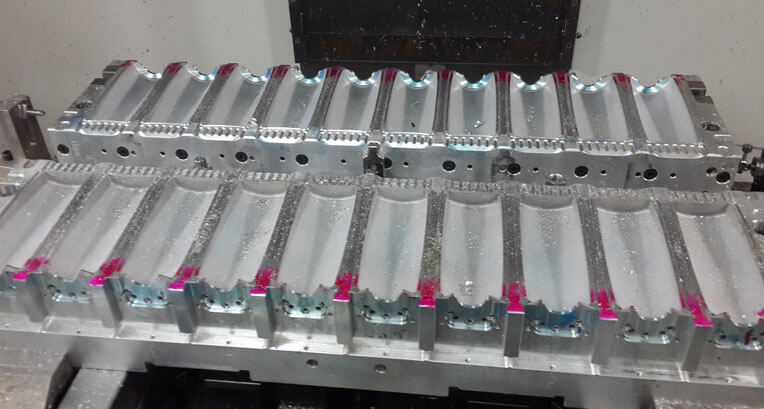

done_allSOPRO MOLDS

According to customer requirements, with the highest quality standards, we offer the manufacture of Thermoplastic Blow molds for articles such as containers, bottles, food industry, cosmetics and industrial and agricultural fluids.

Specific materials that guarantee mold durability and efficiency are part of its components, High Alloy 7075 Aluminum, AISI 420 Martensitic Stainless Steels, as well as their precision of development, for optimum performance and productivity.

done_allPRODUCT DEVELOPMENT

The plastic injection mold industry is constantly evolving due to a very competitive market. At YAMATO we have a wealth of experience in this product, and we can work closely with each customer from the design phase and throughout the process to optimize the performance of their molds. In addition, production volumes require high quality molds and very short lead times.