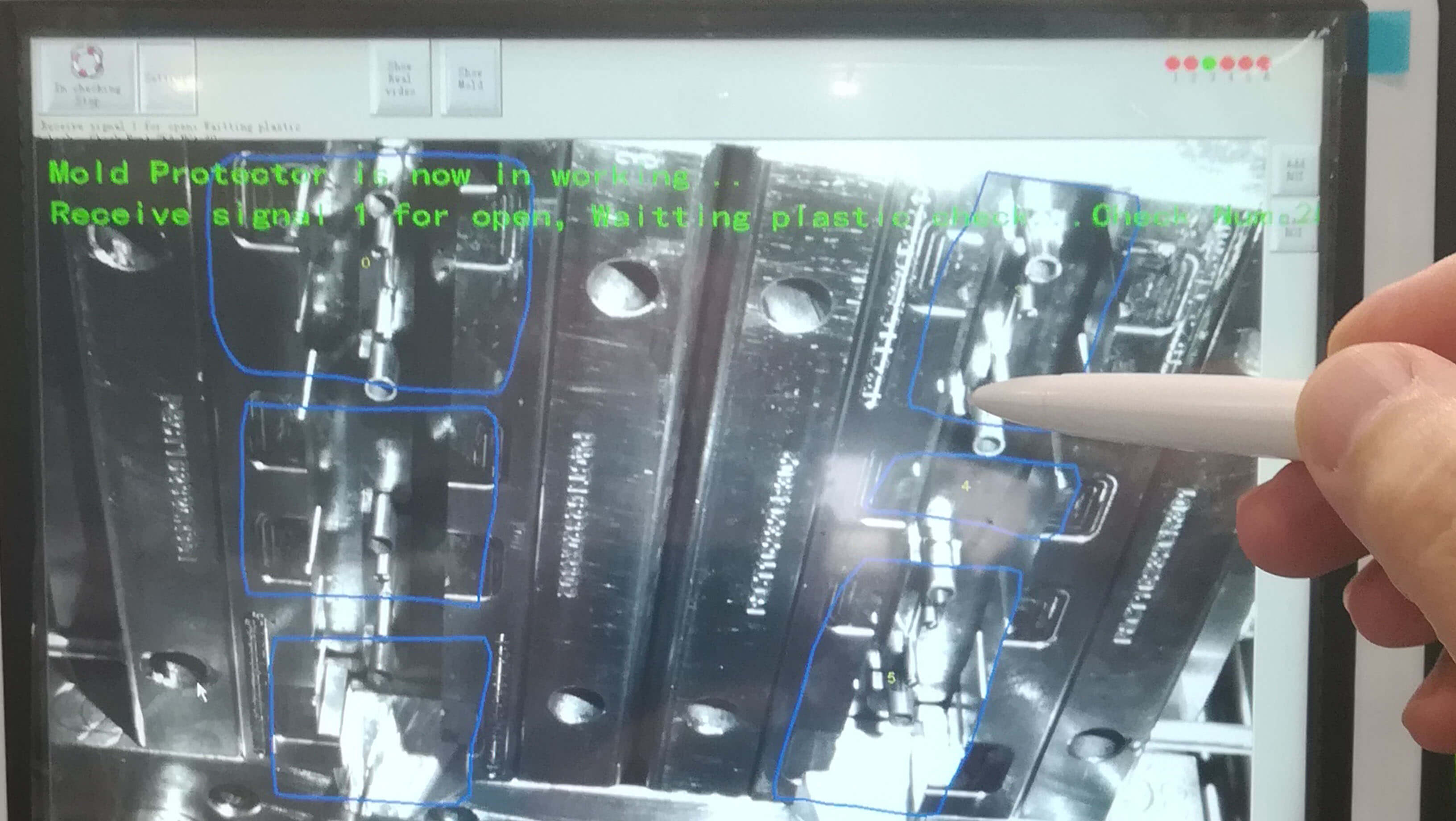

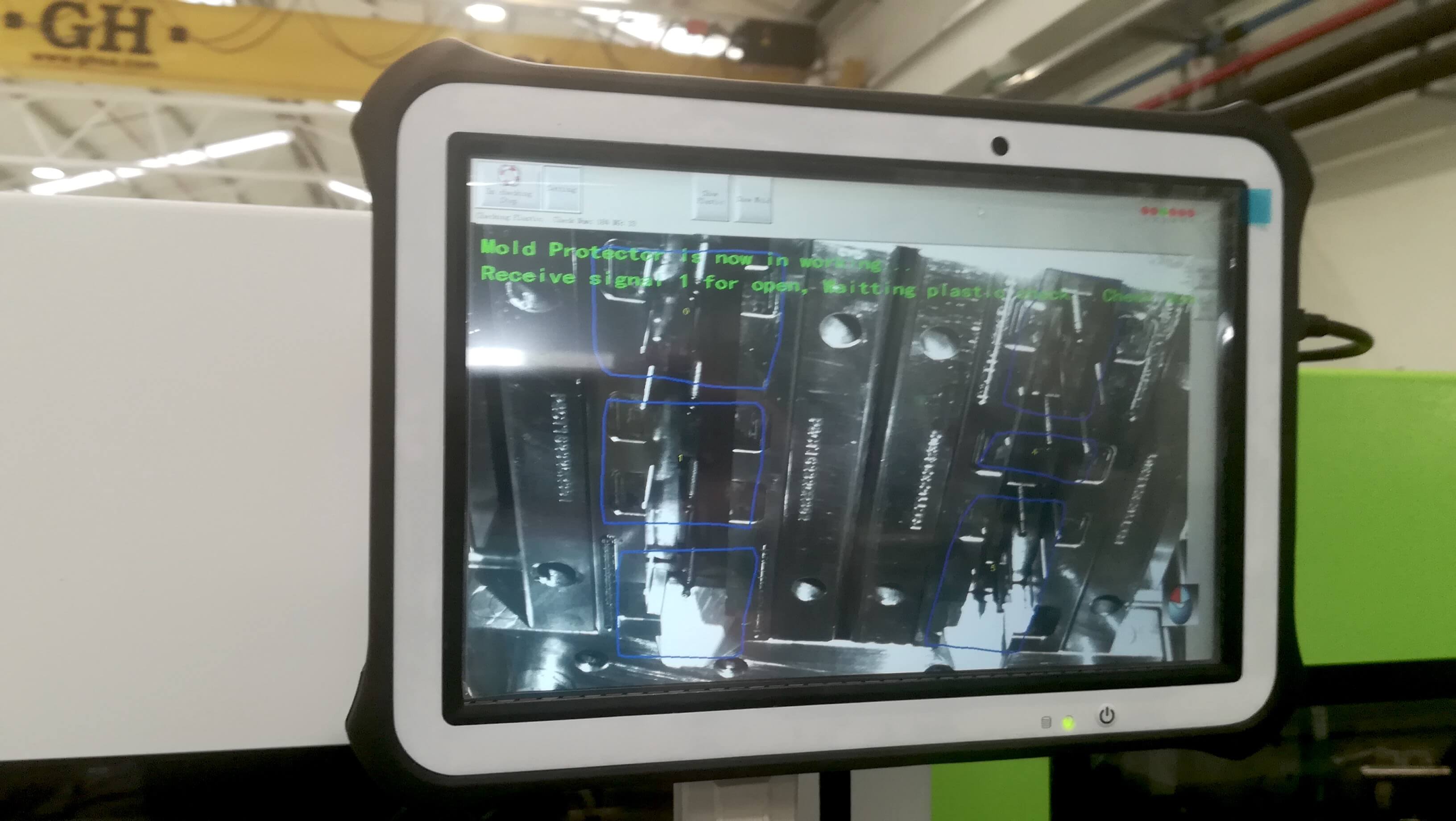

Yamato Vision Image detector

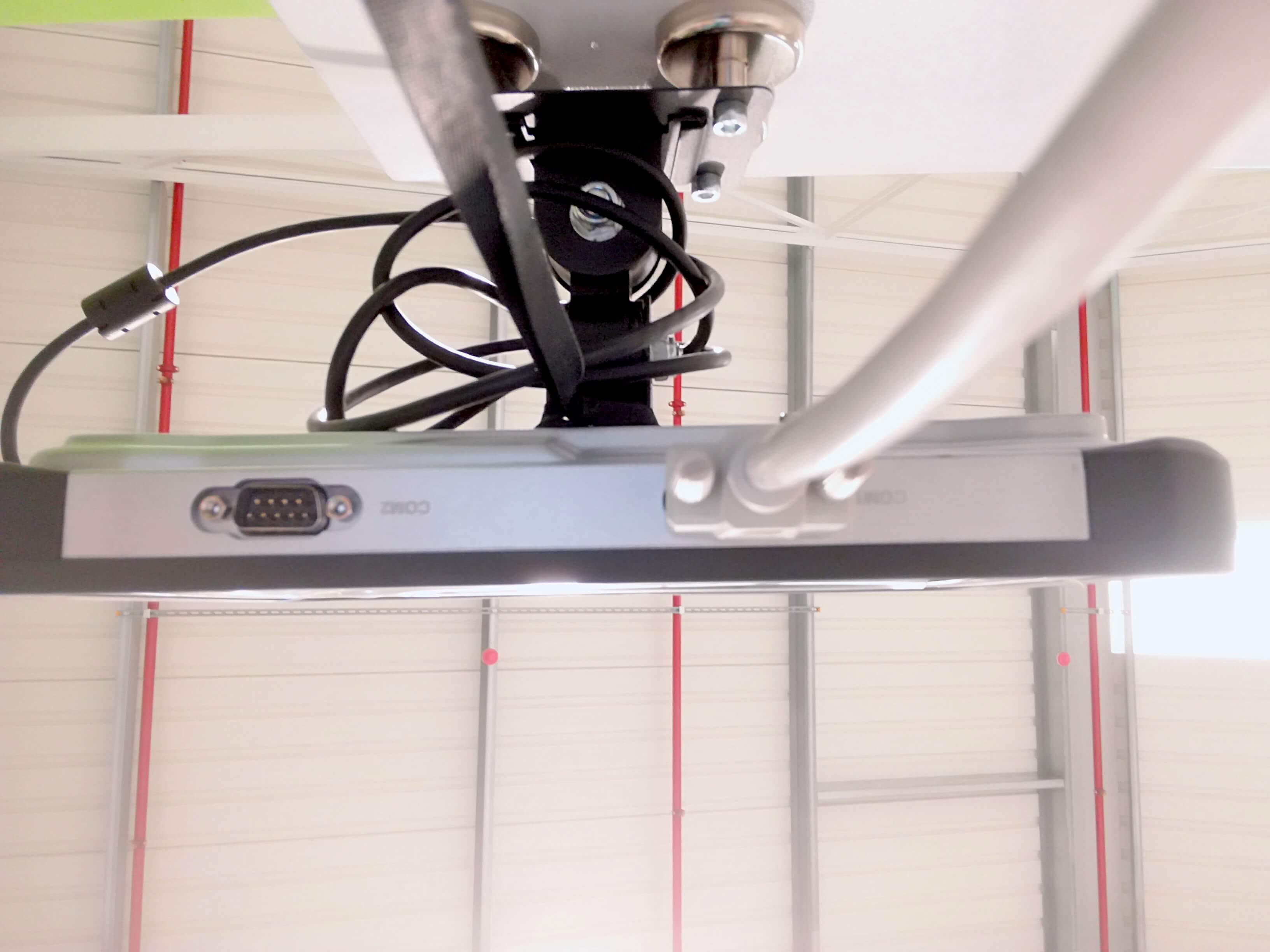

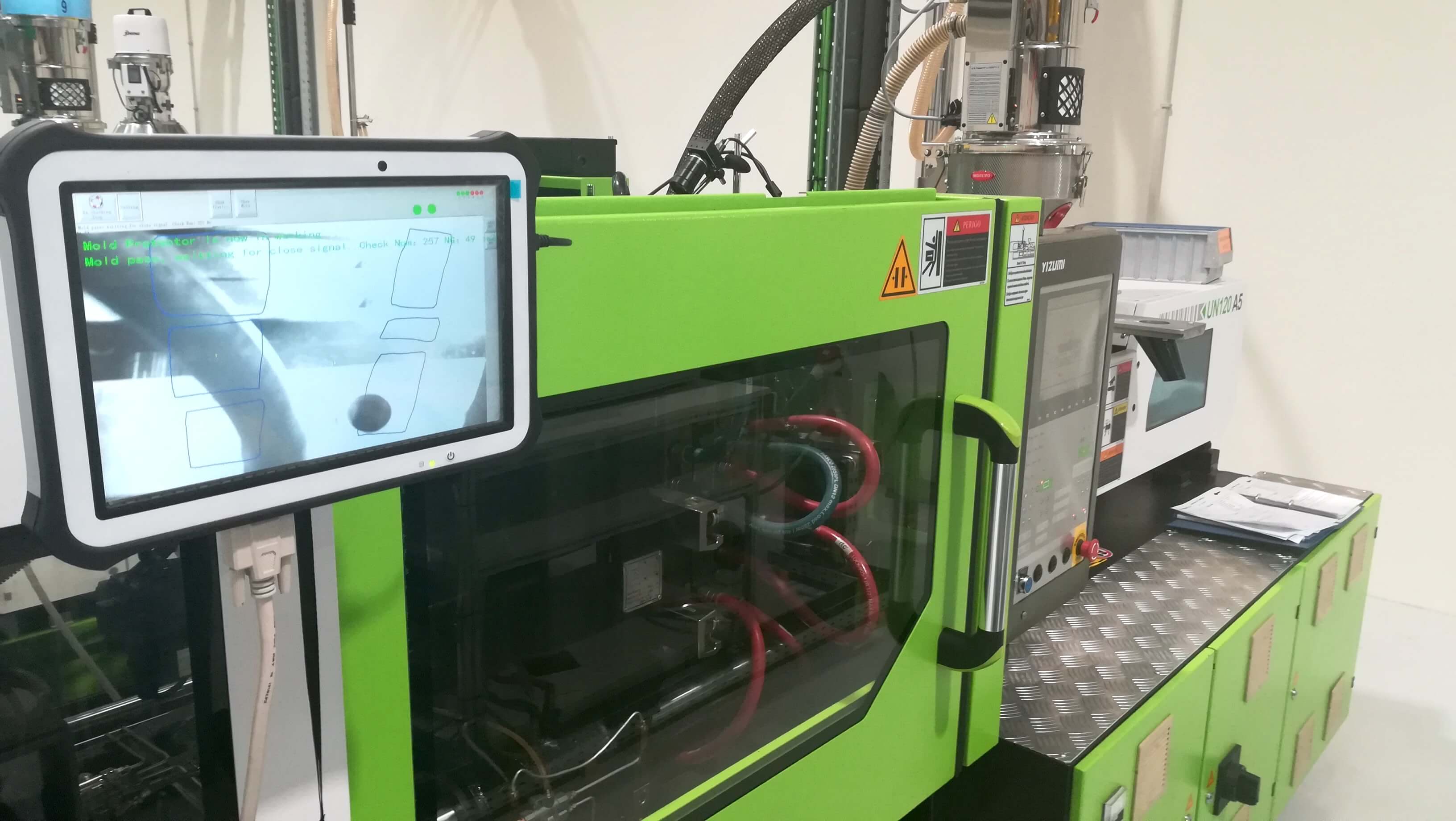

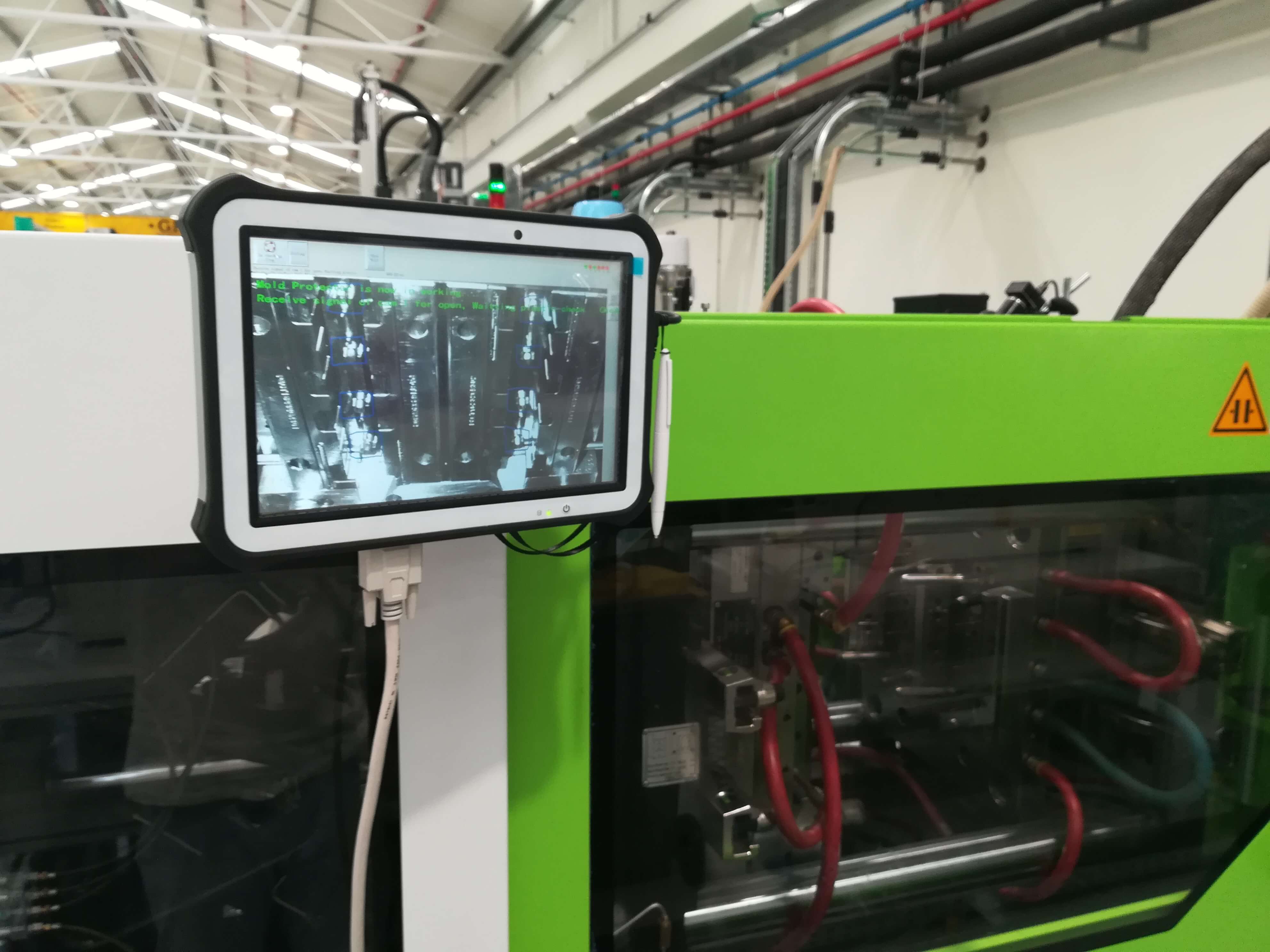

The Yamato Vision Image detector integrates the most advanced vision, optics, electronics and control system for automation processes in the plastics and metalworking industry.

A large number of successful applications give us extensive control and safety experience applied to a wide range of injection machines in the US, Europe, Japan, Taiwan, including International-class customers such as Siemens, Panasonic, AOC, quantcomputer, Foxconn etc.

As the most important tool in the plastics and metalworking industry we can consider the quality and durability of the mold and die before the product itself. The mold / die occupies a very high cost within the manufacture of a plastic part and therefore its safety during the production process is key to its viability.

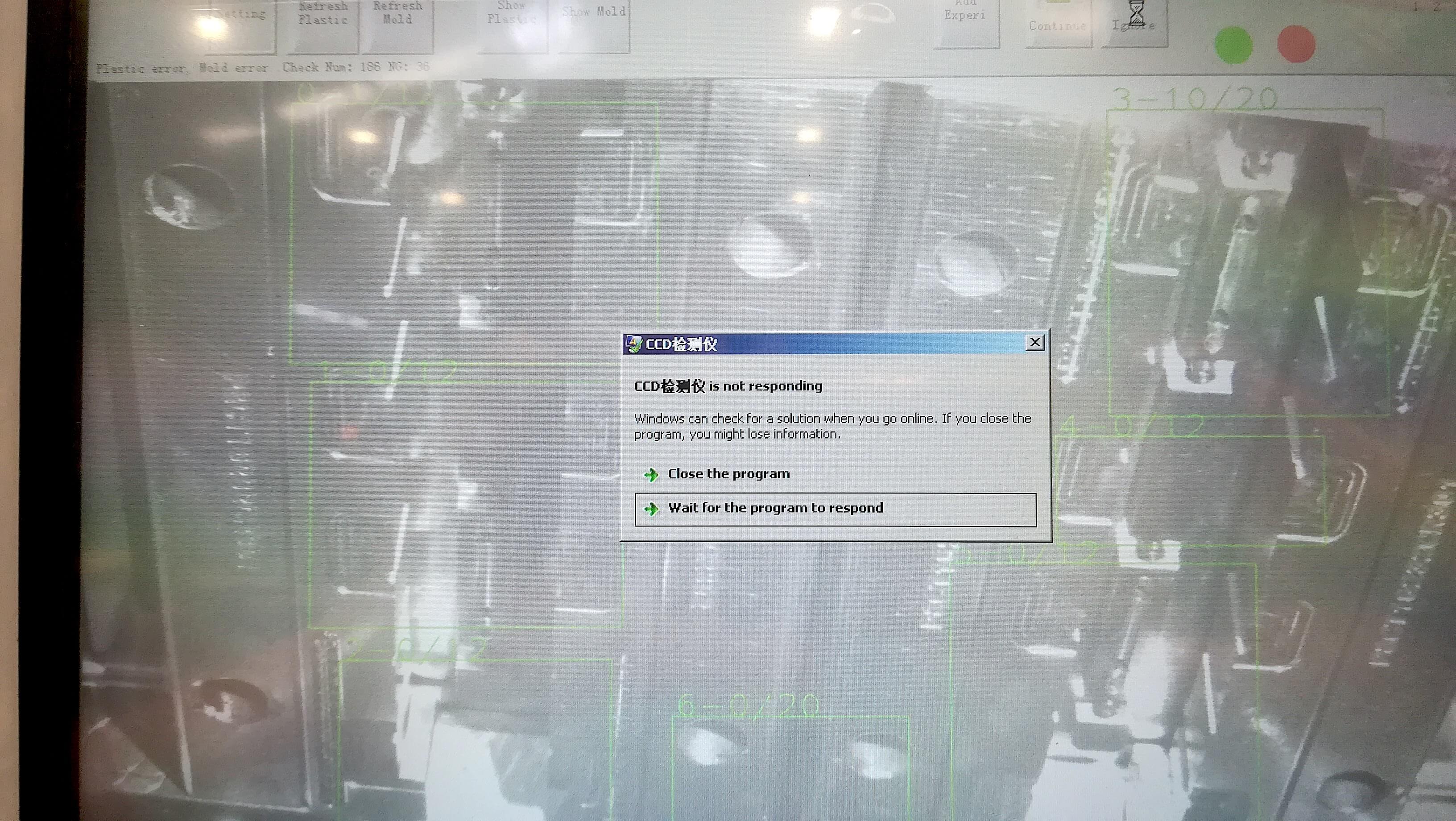

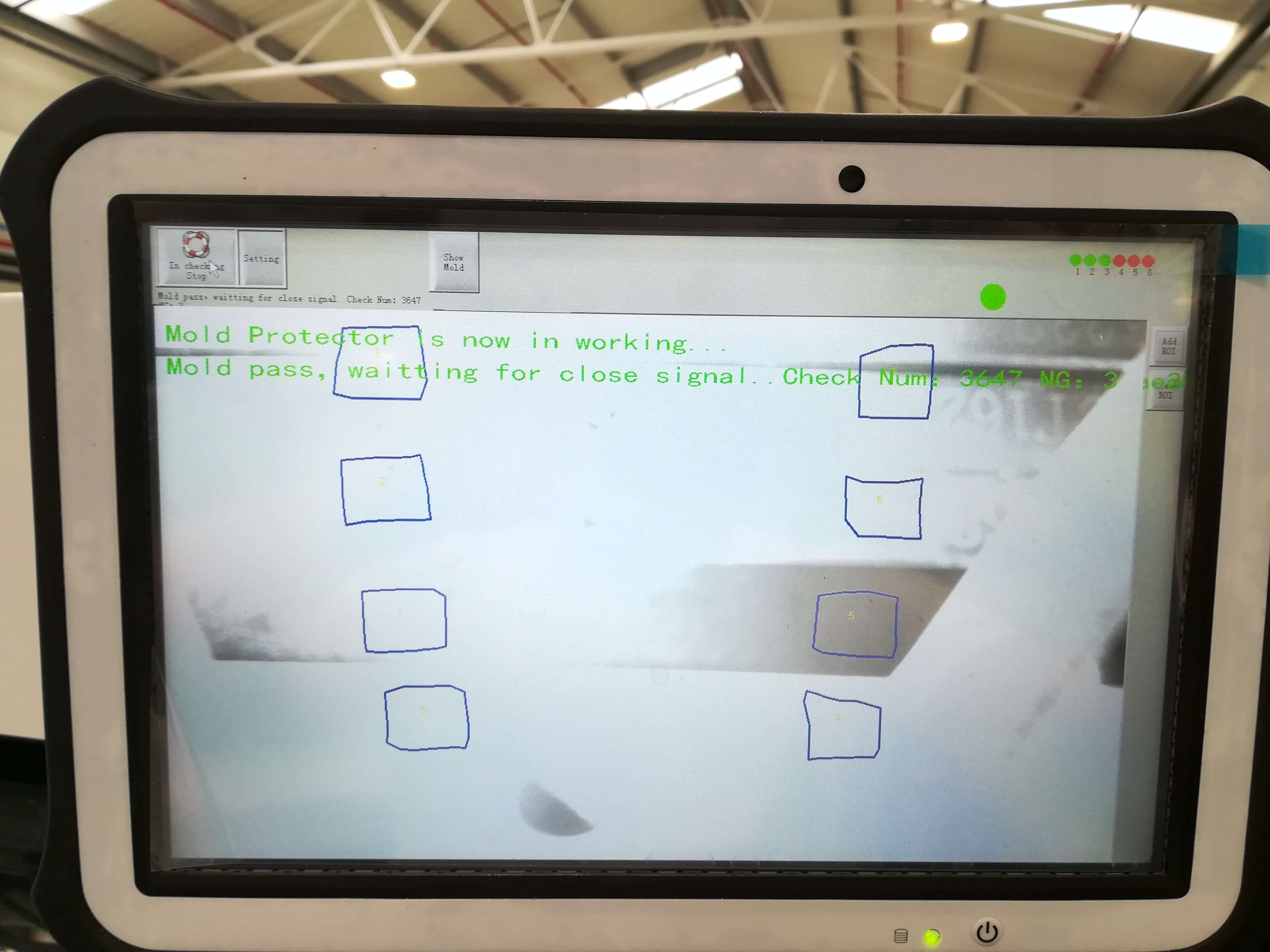

Focused on mold safety and protection, preventing breakage, unplanned downtime, carelessness, clogged cavities, fouling, remaining parts and nozzles, cars or ejectors out of position, the Yamato Vision System alerts you to possible damage that could be caused by these situations. that occur daily inside a plastic injection mold during its operation, thus saving thousands of dollars on repairs that could have been avoided by having a secure system to oversee these processes. This is manifested in cost savings and increased efficiency.

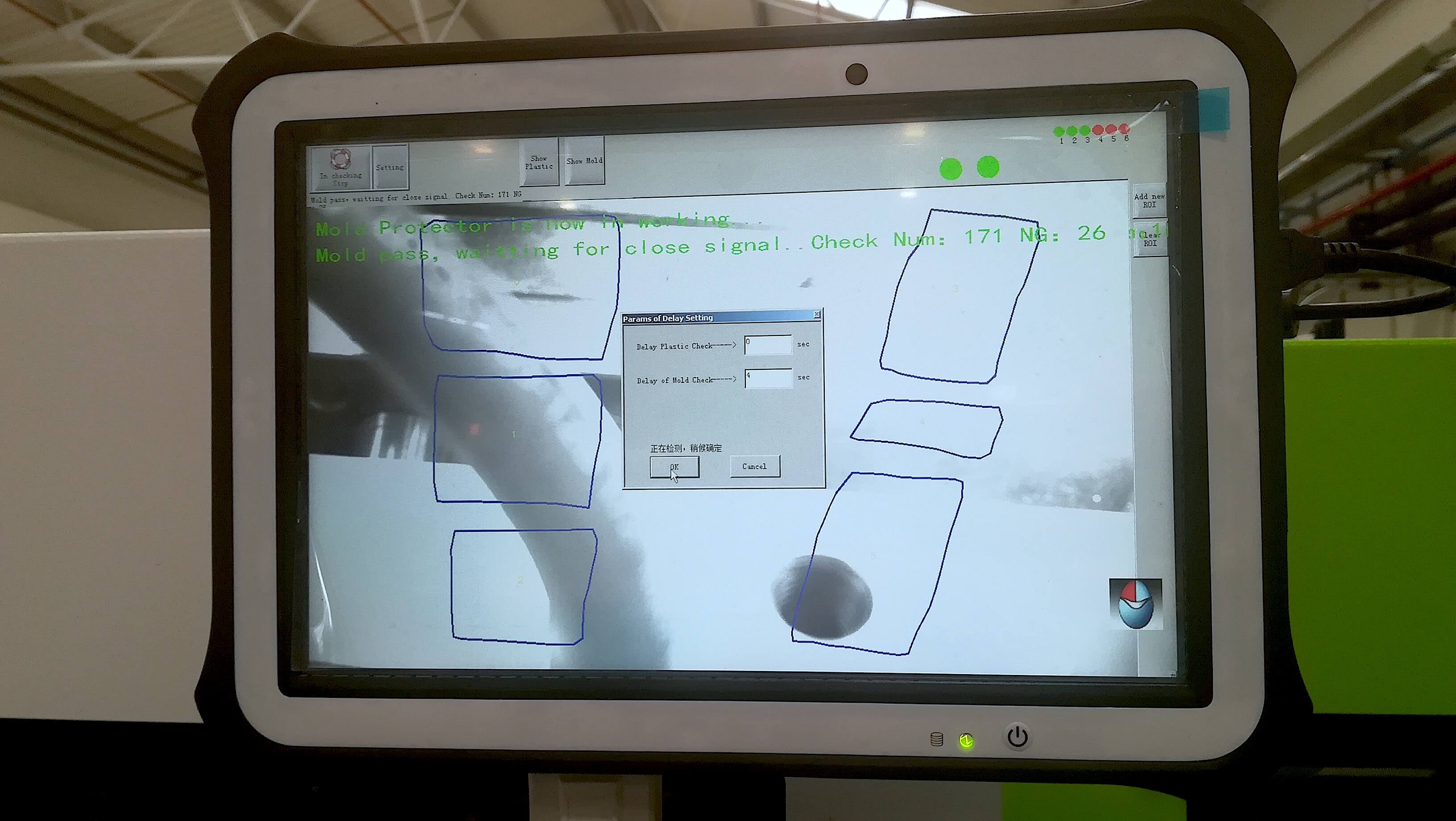

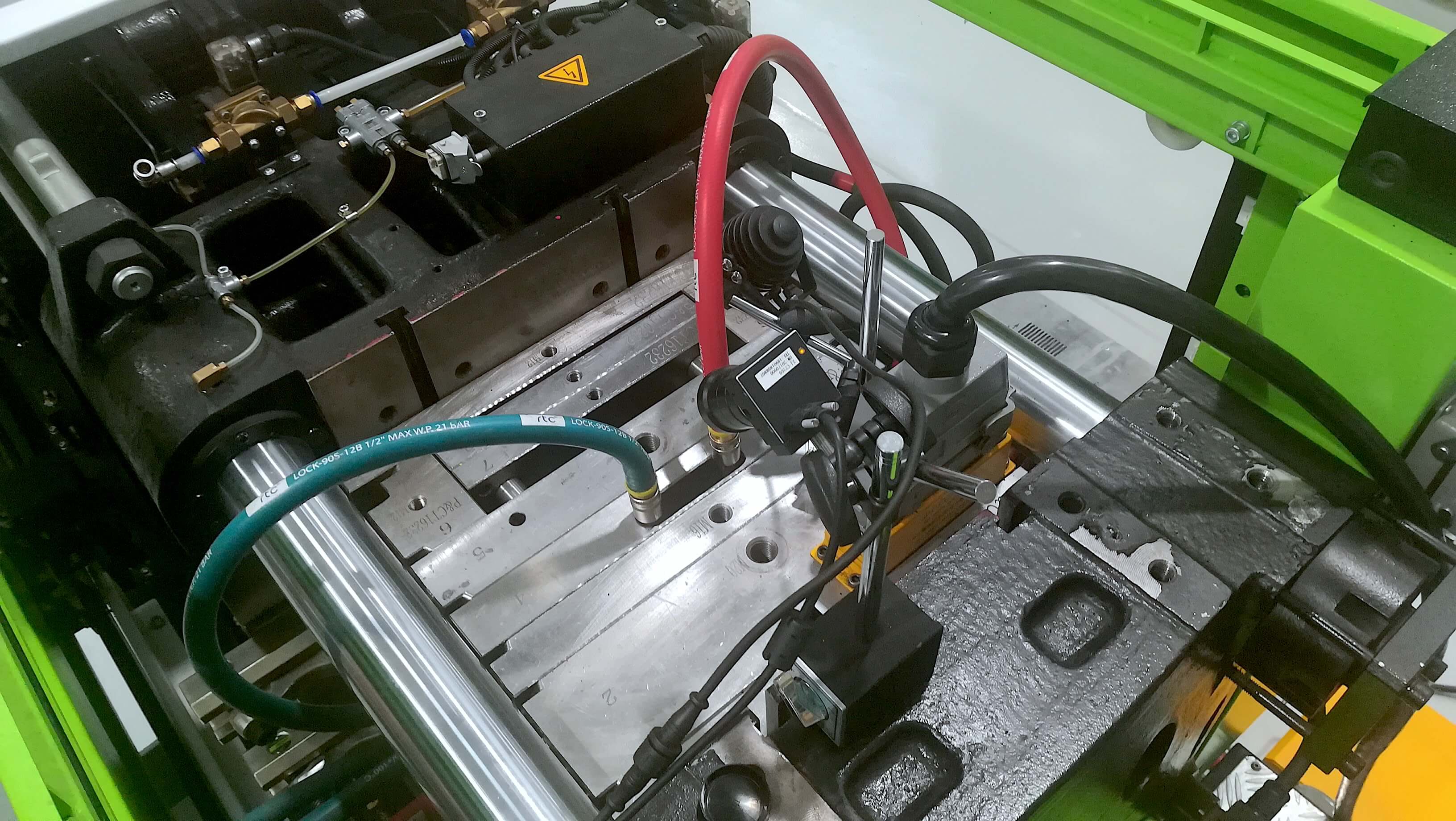

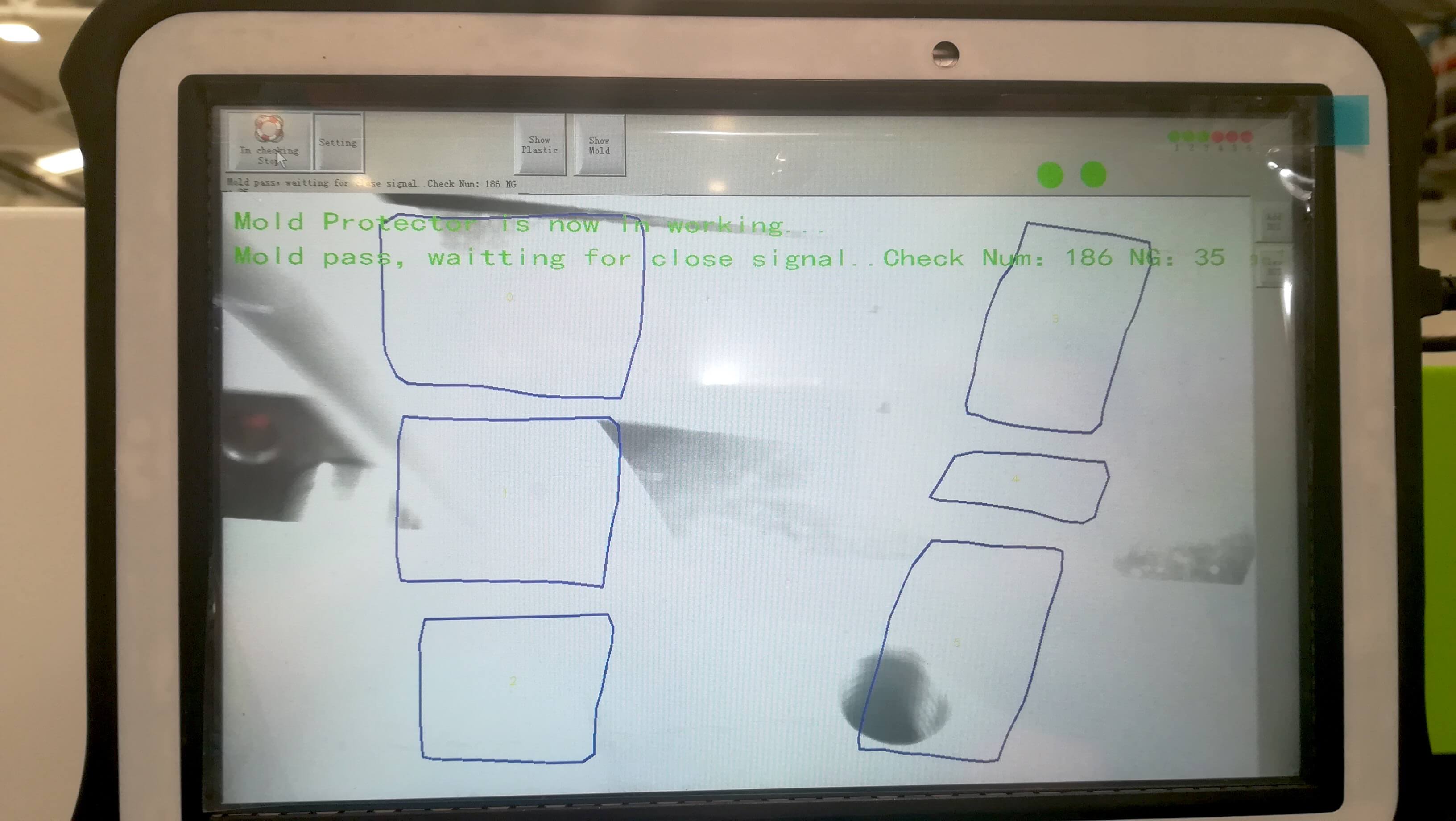

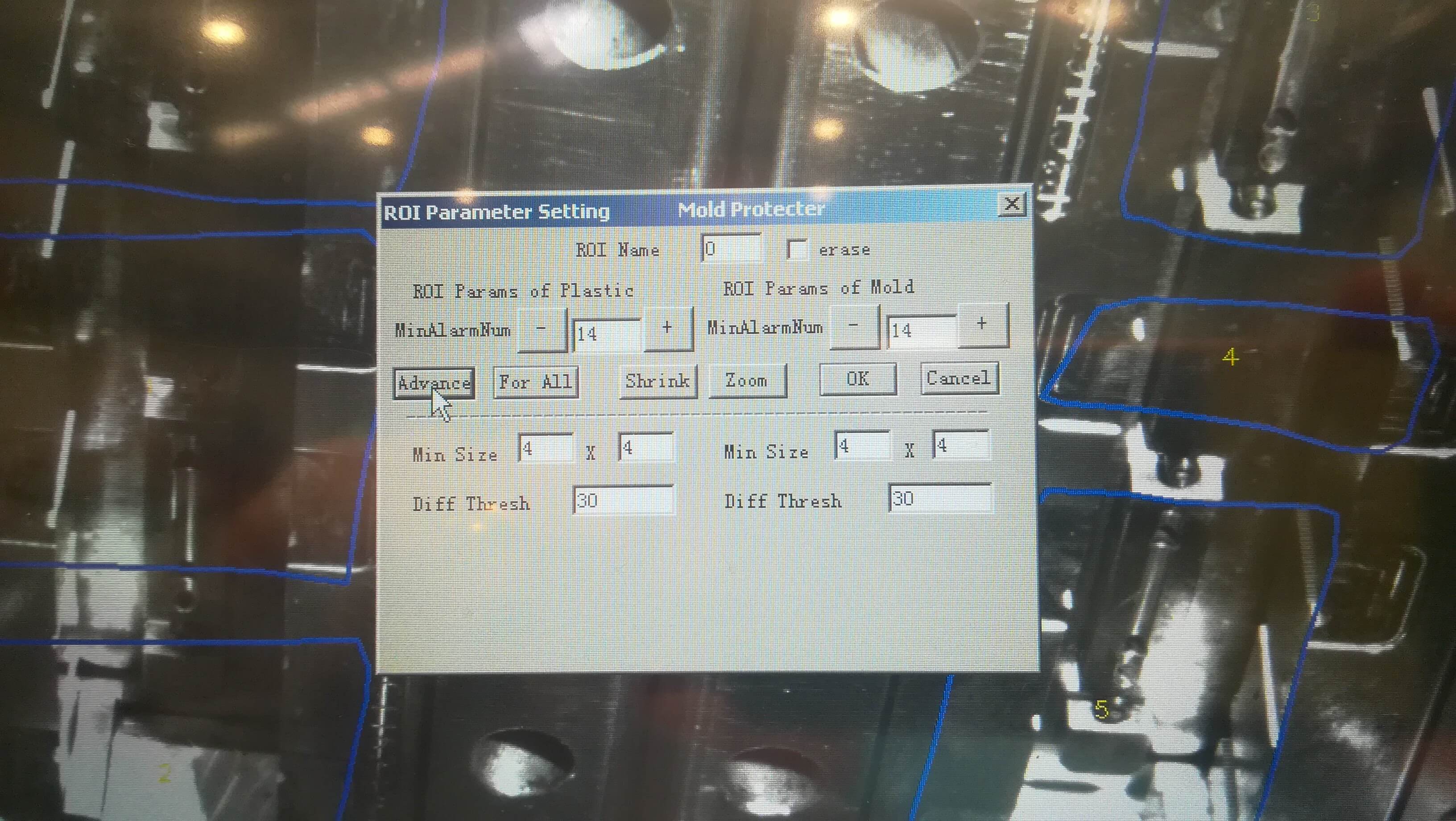

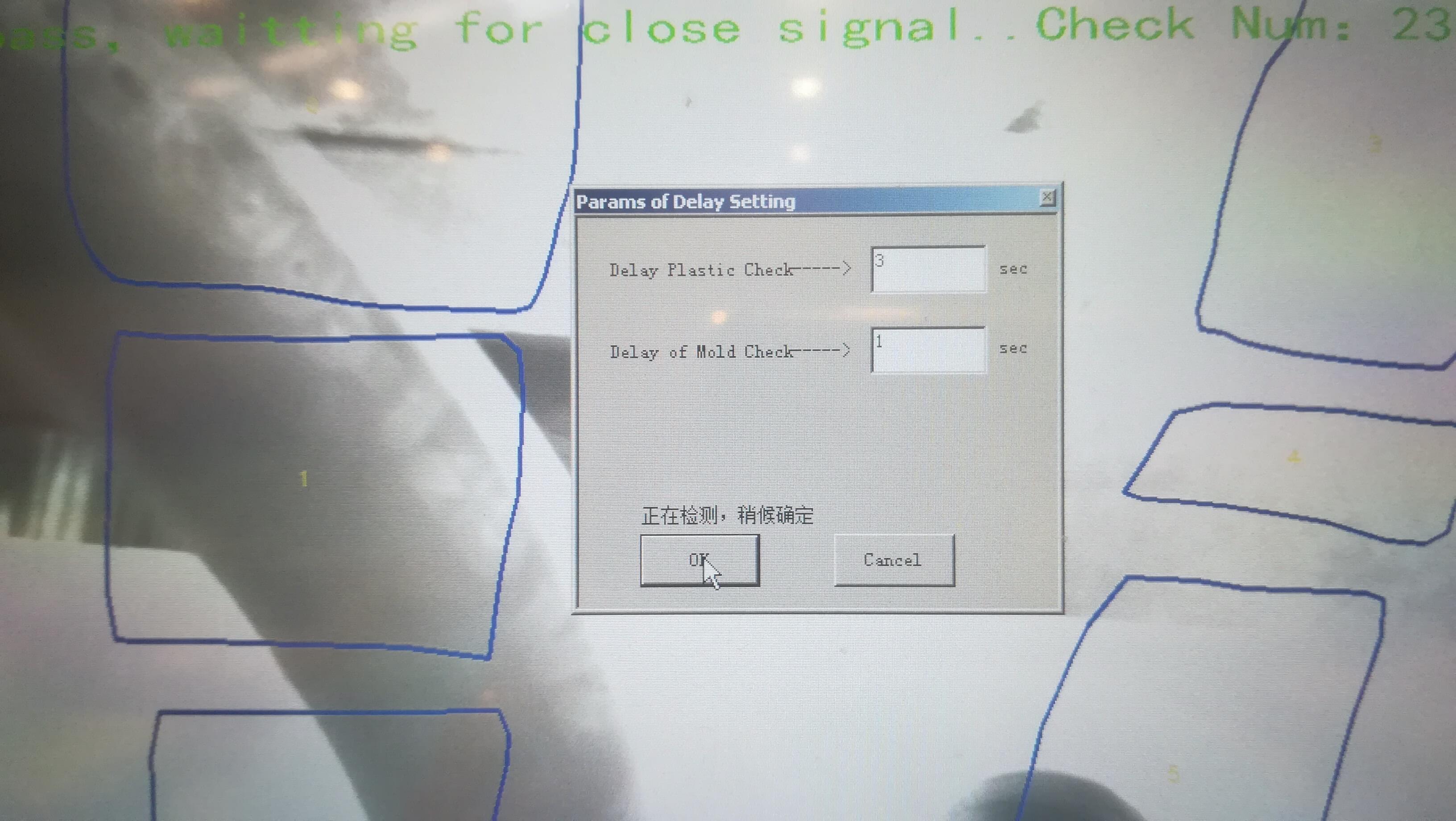

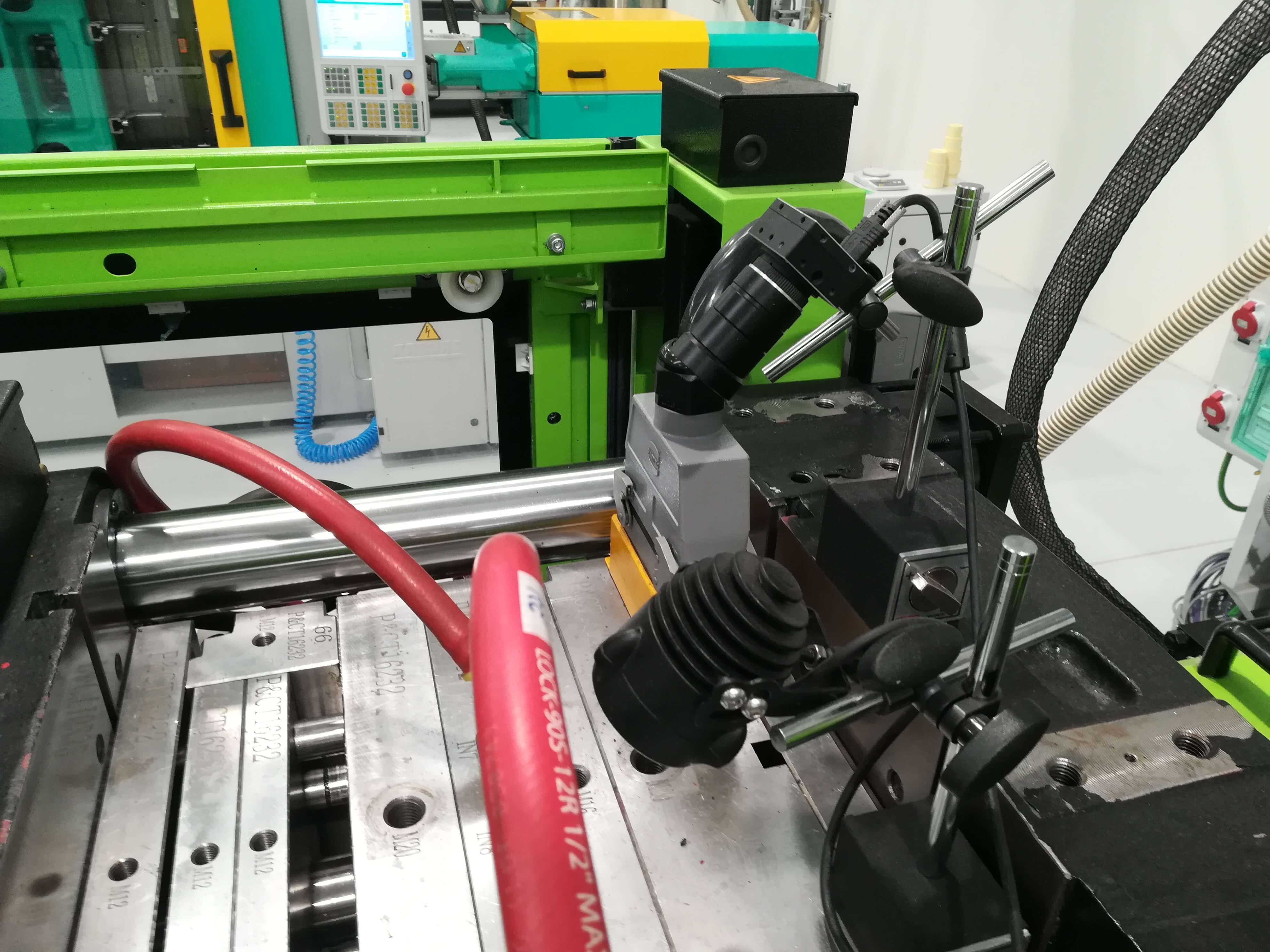

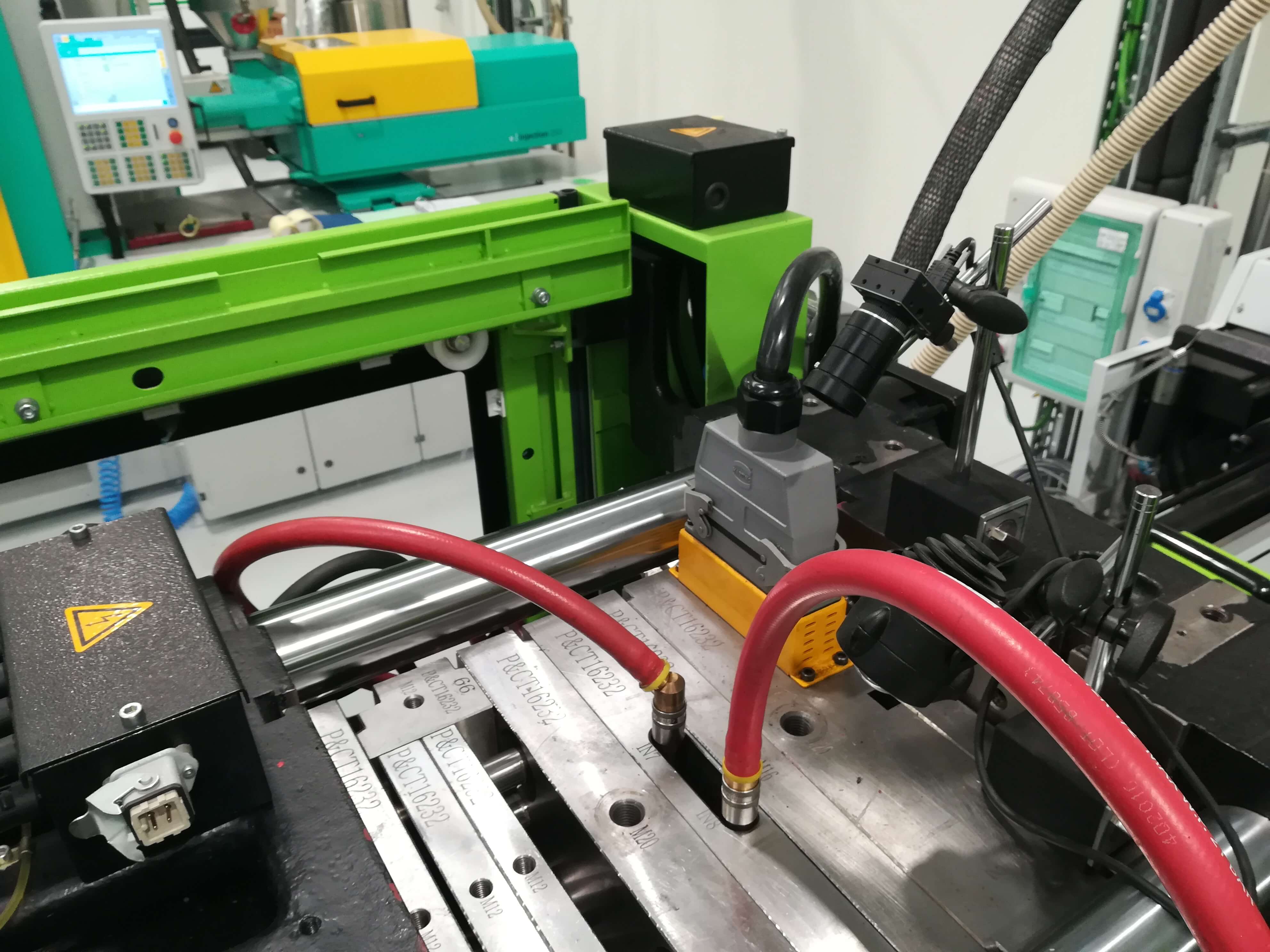

Very easy to install with a very simple and user-friendly programming system. Yamato Vision System can control the following:

- Confirm that the cavity is clean and unoccupied before closing the mold.

- Confirm that the cavity is clean and unoccupied before closing the mold.

- Confirm the position of the ejectors.

- Confirm the position of the carts, slides, and other moving parts within the mold.

- Confirm the presence of inserts to be overmolded.

- Detect foreign elements within the mold.

- Detect burrs, incomplete piezas.

- Detect missing parts.

- Detect a shape change of the part.

- Reduce excess ejection movements.

- Reduce staff at the foot of the machine.

- Gives customer confidence, avoids rejections and returns.

- Prevents damage and therefore delays in production delivery.

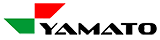

Featuring an easy-to-program, touch-screen display with detection speeds of 1600 images / minutes, infrared lamp and high-resolution cameras, Yamato vision is the most cost-effective choice in custody and long life of its molds.